Manufacturers & Environmental Product Declarations (EPDs)

Did you know that products having EPDs (Environmental Product Declarations) can contribute to many third-party green building ratings systems and green codes?

While each rating system (such as LEED*, Green Globes*, and Envision*) and code (such as CALGreen and International Green Construction Code) may evaluate the contribution of an EPD in a different way, all require a certain amount of products to have EPDs to meet criteria for either points towards certification or code compliance.

Why is this important for MEP products and manufacturers?

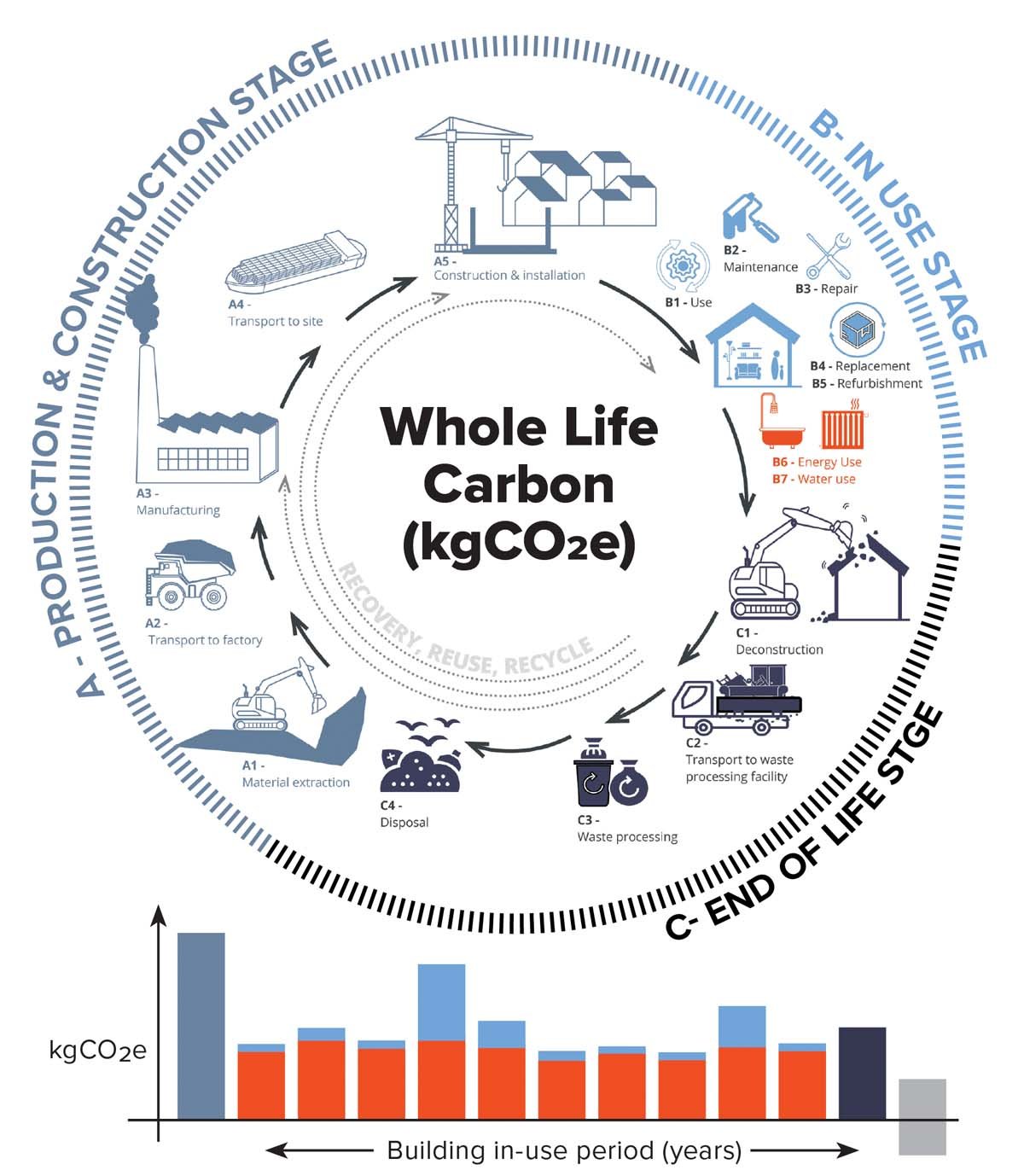

A substantial amount of embodied carbon (embodied energy) is used to manufacturer products and components, such as piping, fixtures, and mechanical equipment, and often the MEP systems are some of the top first cost budget items on a project. Some components, such as piping have a potential long-term duration in a building, and other equipment with possible replacement every 10-15-20 years.

When seeking to optimize how a product is made, we reference the time tested saying of “you can’t manage what you haven’t measured” … and gathering EPDs from potential suppliers gives you the starting point to be able to assess the impact of your purchases for your projects. If you are a manufacturer, the life cycle assessment process to obtain an EPD helps you better understand the impact that raw material use, energy to fabricate, as well as transportation have on your final products environmental impact.

EPDs are a valuable way to inform your production processes as well as support individual project pursuits for certification and code compliance.

Below are a few of the areas where MEP EPDs can help meet sustainable building criteria:

LEED v4 & v4.1 – Environmental Product Declarations Option 1 & Option 2

Green Globes New Construction 2024 – 5.1.1 Whole Building Life Cycle Assessment & 5.2.1 Product Life Cycle

BREEAM v7 – Mat 01 Building Life Cycle Assessment & Mat 02 Environmental Product Declarations

BREEAM v6 – Mat 01 Life Cycle Impacts

Living Building Challenge 4.1 – 07 Energy Petal Embodied Carbon

2025 CALGreen – Section 5.409.2 (Insulation Only), 5.409.3.1 (Mineral Wool Board Insulation Only), A5.409.2.2 Tier 2 (Insulation Only) & A5.409.2.3 (Mineral Wool Board Insulation Only)

International Green Construction Code & ASHRAE 189.1 – 901.4 Environmental Product Declarations & 901.5.2 Life-Cycle Assessment

Image courtesy Canadian Architect

-

Creating a company plan - Buro Happold

By adopting this Challenge, each MEP engineering and design firm is confirming that it will establish a company plan to reduce operational and embodied carbon across MEP systems on all projects, targeting zero by 2040. Measure and report progress against that plan annually.

-

Refrigerants overview

By adopting this Challenge, each MEP engineering and design firm is confirming that it will request low-GWP refrigerant availability when designing systems to reduce or eliminate GHG emissions from refrigerants.

-

Requesting EPDs

By adopting this Challenge, each MEP engineering and design firm is confirming that it will request Environmental Product Declarations (EPDs) in project specifications for MEP system components

-

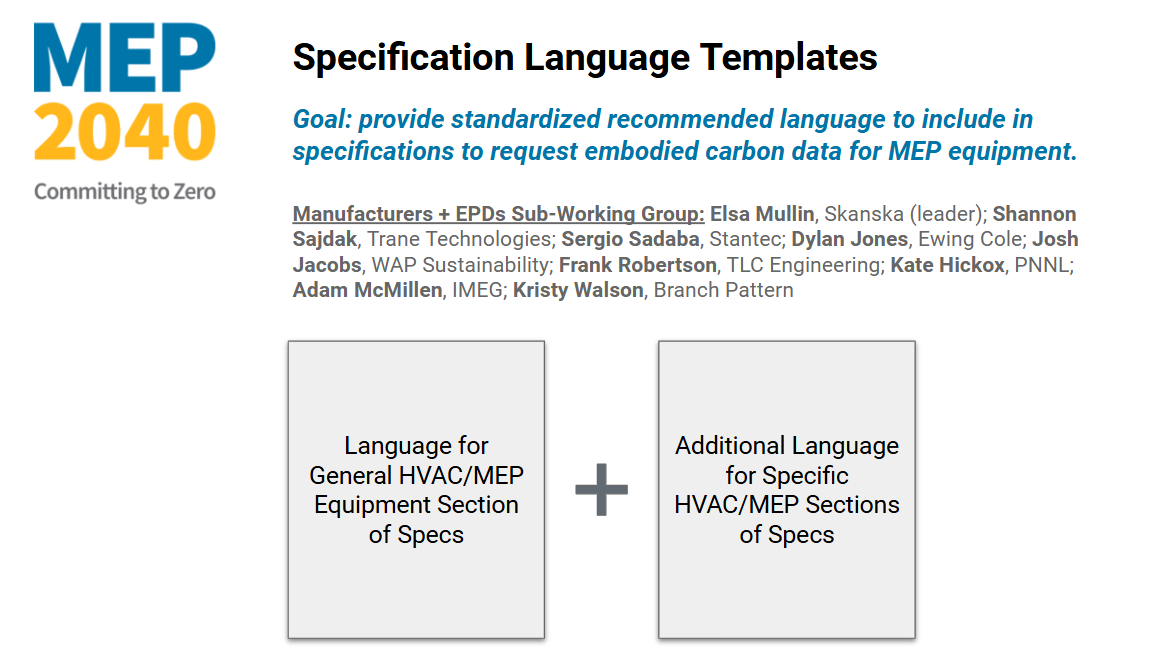

Specification Language Templates

Recommend to include in most general/overarching section of specs for HVAC/MEP Equipment. Includes detailed list of references (Model LCA Specifications from CLF, TM65 methodology, Carbon Definitions for the Built Environment, etc.) and definitions (EPD, Embodied Carbon, LCA, PCRs, TM65, etc.)

In “submittals” subsection, asks for embodied carbon submittals. Includes proposed language around: 1) how to determine which equipment requires embodied carbon data; 2) Hierarchy of data sources for embodied carbon.

Resources to support the Commitment are crowd-sourced. Please submit resources such as company reports, company plans, case studies, research papers, or tools you think may be helpful to others. The MEP 2040 website will link to external publicly available locations such as web pages, and storage places such as Google Drive, Dropbox, or OneDrive.